Specifications

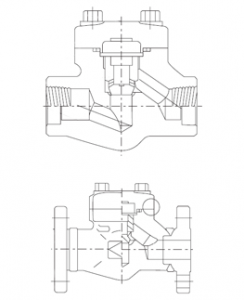

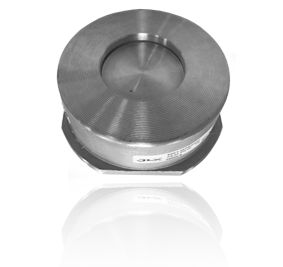

It is a forged reduced or full bore valve, piston, ball or Swing check type, horizontal or vertical mounting, manufactured according API standard.

It is a forged reduced or full bore valve, piston, ball or Swing check type, horizontal or vertical mounting, manufactured according API standard.

- In accordance with NACE MR01/75.

- Full bore (FB) or reduced bore (RB).

- Bolted or welded cover.