Specifications

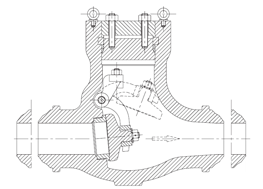

It is a casted or forged Swing check valve for high pressure, No penetration of hinge pin to outside eliminating possibility of pin seal leakage and allowed for in-line service.

It is a casted or forged Swing check valve for high pressure, No penetration of hinge pin to outside eliminating possibility of pin seal leakage and allowed for in-line service.

- Body-bonnet gasket with closing at pressure – Pressure is used to create a hermetic closure. The higher the pressure, the more hermetic the closure.

- TRIM completely Stellite coated – Long-lasting disk, seat and back-seat of surface.

- Welded seat – Eliminates leak between seat and body, does not loosen due to temperature fluctuations or vibrations.