Specifications

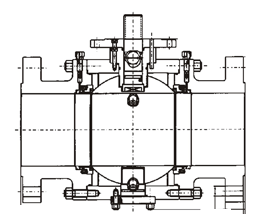

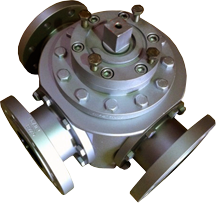

The ball is supported by a lower Trunnion and the body is forged.

The ball is supported by a lower Trunnion and the body is forged.

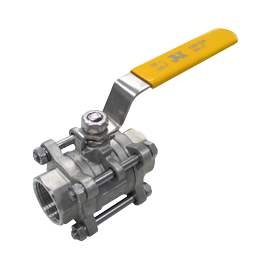

- Three-pieces design for forged body

- Fire-safe, anti-static device and non-ejectable stem

- Up-stream sealing

- Self-relieving seat system

- Double block and bleed function

- Emergency sealing injection system

- Extended stem for cryogenics service