Specifications

Check valves with free flow in one way and blocked in the other way for preventing reverse flow and stopping back pressure in hydraulic and pneumatic circuits. In the valve, there is an automatic lock system with a piston and a spring. Pressure up to 400 bar. The standard minimum differential pressure is 0.5 bar.

Check valves with free flow in one way and blocked in the other way for preventing reverse flow and stopping back pressure in hydraulic and pneumatic circuits. In the valve, there is an automatic lock system with a piston and a spring. Pressure up to 400 bar. The standard minimum differential pressure is 0.5 bar.

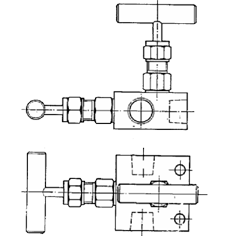

- Range of 2-, 3- and 5- valve instrument manifolds

- The 2-valve manifolds are designed for static pressure and liquid level applications

- The 3- and 5- valve manifolds are designed for differential pressure applications

- It’s usually connected to a static pressure transmitter of gauge

- It’s also used for the isolation or calibration of gauges, thermometers, pressure switches, etc.