Specifications

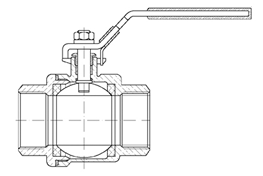

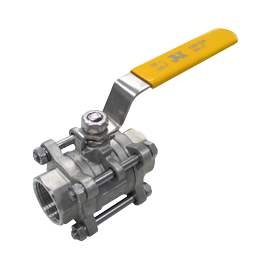

It is a simple ball valve, light and economical to use in general services and purges.

It is a simple ball valve, light and economical to use in general services and purges.

- Screwed two-part split body

- Full bore (FB) or reduced bore (RB) at customer’s request

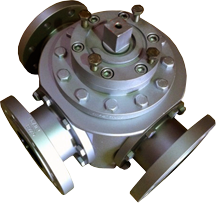

- Ends may be flanged, screwed or socket weld (SW)

- Valves may be fire tested at customer’s request

- Top flange ISO 5211