Specifications

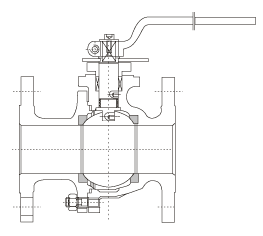

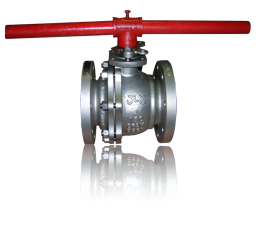

The ball is supported by two soft seats, usually PTFE.

The ball is supported by two soft seats, usually PTFE.

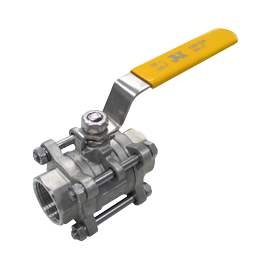

- Two-piece (split body) design for cast body and body connector; two- or three-part design for forged body and body connector.

- Fire-safe, anti-static device, non-ejectable stem.

- Full bore (FB) or reduced bore (RB).

- Minimum torque value.

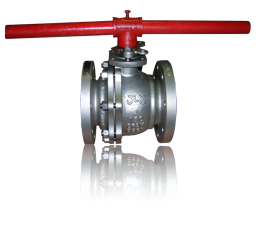

- Blocking system and open/closed lever indicator.

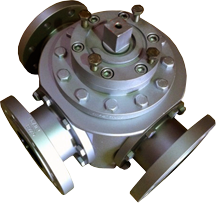

- Top flange ISO 5211.

- Extended stem for cryogenics service.