Specifications

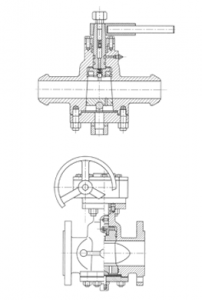

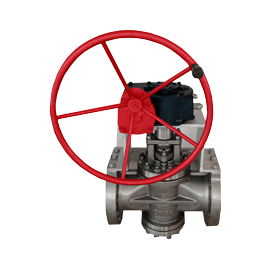

The valve is a «pressure balanced», inverted type, lubricated taper plug valve. The plug has 2 balancing holes connecting the chambers at each end of the plug with the port. This maintains balance and prevents taper locking. Tight shut-off is ensured by lapping the plug to fit precisely inside the body and by injection of a film of lubricant, which stops leakage and prevents penetration of dirt into the seating area. It is used with a lubricant generally based composite with improved viscosity oil which is injected under pressure between the plug and the body seat to reduce friction in seals.

The valve is a «pressure balanced», inverted type, lubricated taper plug valve. The plug has 2 balancing holes connecting the chambers at each end of the plug with the port. This maintains balance and prevents taper locking. Tight shut-off is ensured by lapping the plug to fit precisely inside the body and by injection of a film of lubricant, which stops leakage and prevents penetration of dirt into the seating area. It is used with a lubricant generally based composite with improved viscosity oil which is injected under pressure between the plug and the body seat to reduce friction in seals.

- Logical structure, reliable sealing and excellent action.

- Pressure balance structure with encapsulated plug and position indicator.

- There is an oil lubricator between the valve body and the seal surface which allows the gasket to be lubricated and the sealing capacity to be increased.

- Flange materials and dimensions will be selected depending on users’ requirements.