Specifications

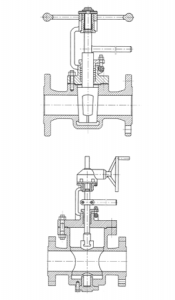

To open Lift plug valve, we should turn the hand wheel to make the plug rotate towards the opening direction. Then, the plug is lifted and separated from the sealed surface. At that time, operator should further turn the handle by 90° to make the channel of plug connect with the channel of valve body. Then, the valve is opened. During the valve opening and closing process, the sealed surface is taken off. Thus, there is no abrasion on the sealed surface.

To open Lift plug valve, we should turn the hand wheel to make the plug rotate towards the opening direction. Then, the plug is lifted and separated from the sealed surface. At that time, operator should further turn the handle by 90° to make the channel of plug connect with the channel of valve body. Then, the valve is opened. During the valve opening and closing process, the sealed surface is taken off. Thus, there is no abrasion on the sealed surface.

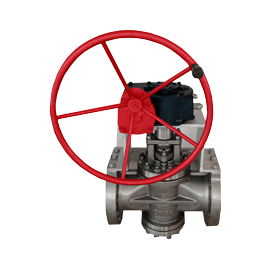

- The product has reliable seal and excellent action

- Valve opens and closes while seal surface withdraws, therefore not causing abrasion

- Installation in any position

- Valve part materials and flange sizes may be configured to customer’s requirements