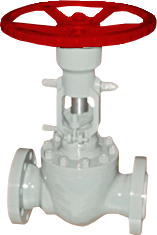

Specifications

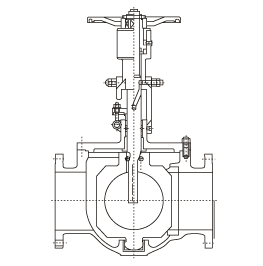

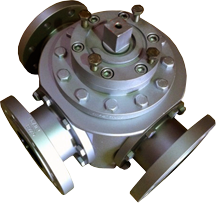

Orbit Ball Valve incorporates a proven tilt-and-turn operation that eliminates seal rubbing, which is the primary cause of valve failure. The maintenance can be from top of valve without dismounting it from installation.

Orbit Ball Valve incorporates a proven tilt-and-turn operation that eliminates seal rubbing, which is the primary cause of valve failure. The maintenance can be from top of valve without dismounting it from installation.

- Single-part body

- On-line maintenance

- Low torque operation

- Emergency sealing injection

- Reliable sealing

- Double block and bleed function

- Fire-safe and anti-static design

- Extended stem

- Top flange ISO 5211