Specifications

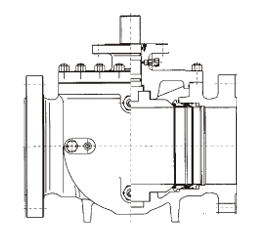

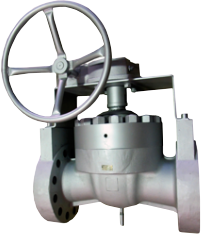

The ball is supported by a lower Trunnion and internal parts are accessible from the top of the valve.

The ball is supported by a lower Trunnion and internal parts are accessible from the top of the valve.

- Single-part body design

- Fire-safe and anti-static device

- On-line repair

- Lower pressure loss compared with side-input design

- Double block and bleed function

- Emergency sealing injection system

- Extended stem for cryogenics service

- Top flange ISO 5211